Winchester’s Super X Pump: Legendary Lineage & Superlative Speed

When introducing the Model 12 (actually named the 1912 for the year it was released) marketers for the Winchester Repeating Arms Co. dubbed the do-all, slide-action shotgun “The Perfect Repeater.” At the time, it was. It borrowed mechanical design traits from the godfather of all repeating shotguns—Winchester’s John Browning-designed Model 1897—but improved on it in myriad ways, most strikingly with an internal hammer and a British-style stock design that were both less rifle-like and more conducive to instinctive wingshooting.

The Model 12 remains one of the most iconic guns of all time, in any category, thanks to its proliferation on trap, skeet and upland bird hunting fields across the country. But it did have one main flaw that caused its discontinuation in 1964: It was made too well.

You see, by the late 1950s, Remington began eating Winchester’s lunch with its very similar Model 870 pump, not so much because the 870 was a better shotgun but rather because it was significantly less expensive, thanks to its cast-and-stamped production method and finishing that didn’t require nearly as much care and handwork as did the Model 12 at its dated New Haven, Conn., facility.

So, around 1960, under the counsel of Winchester engineer Stefan K. Janson, the Olin-owned Winchester firm re-designed many of its guns to conform to more modern manufacturing processes, decreasing the amount of skilled labor and production time—in other words, cost—required of each. One of the first models to come off the new “globalized” line in 1964 was the Model 12’s successor, the Model 1200.

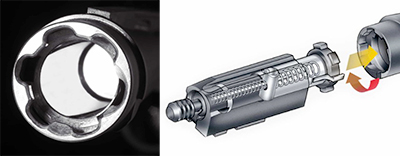

Fieldstripping the Universal Hunter reveals features common to models throughout the SXP line, such as the four-lug bolt head and sliding bolt cover. (btm. l.), removable trigger group (ctr.) and dimpled loading gate (far r.). Note also the gun’s magazine tube (far l.), which is treated to reduce friction.

The 1200 pump gun featured dual action bars, Winchester’s innovative WinChoke removable choke-tube system and a rotating bolt head similar to ArmaLite’s AR-17 semi-automatic shotgun that had debuted just a few months prior. While the 1200 sold reasonably well, there were a goodly number of Model 12 aficionados who simply viewed it as a rougher, less-expensive Model 12—and they were not wrong in this assessment.

“At the time, Winchester had to split its personality,” said Winchester Product Manager Glenn Hatt. “The company knew it had to compete at the base level, so it started casting more and machining less. But it also offered high-end guns to the other end of the market.”

By the late ’70s, the unionized labor situation in New England became even more untenable if the firm was to compete on the world stage and its lower labor costs, and so, in 1981, Olin sold out to its employees and licensed the Winchester name to the newfound U.S. Repeating Arms Co. (USRAC). An updated model 1200 with a 3″ chamber had been in the works since 1978—the Model 1300.

The 1300 also had a rotating bolt head, but that’s when shooters really began to notice that the delayed-unlocking bolt and attached fore-end design provided initial rearward movement of the slide by itself. Here’s how it works:

The four-lug, floating bolt head is slaved to a bolt body by a stud that rides in an angled slot. Within the hollow bolt body, a firing pin return spring provides enough pressure onto the floating bolt head to push it forward, thereby forcing the stud to twist in its slot, rotating the bolt head as it pushes a shell into battery. This rotation aligns the bolt’s lugs behind corresponding lugs on the steel barrel extension so that when a shell is fired, the bolt seizes.

If there is no force upon the bolt face, the bolt can be pulled back with mere finger strength so that the lugs rotate from behind their barrel extension’s lugs, allowing the bolt to be opened. But when a shell is fired, the rearward force of the shell pushes the lugs tightly against the barrel extension’s lugs, preventing the bolt head from rotating. As the recoil impulse begins, the complete gun moves rearward, gaining momentum. After a few milliseconds, the rearward recoil is slowed by the resistance offered by the shooter.

As chamber pressure subsides, the lugs’ bite diminishes, allowing the bolt head to rotate, thereby unlocking it. When they clear the barrel extension’s lugs, the heavy bolt and attached fore-end unit, still having rearward momentum but now unencumbered by the gun around it, moves rearward to initiate the action stroke on its own.

“Think of the bolt and fore-end like a five-gallon bucket of water in the back of a pickup,” Hatt said. “When the truck suddenly brakes, the bucket tries to remain still, but, ultimately, its inertia is overcome and it slides forward in the truck bed even if the truck around it has already come to a full stop. The result is a pump-action that thinks it’s a semi.”

Indeed, the “Speed Pump” action actually felt like it wanted to pump itself; of course, the lack of a return spring prevented the pump from cycling a fresh round into battery, but, nonetheless, the Speed Pump proved faster and more intuitive than competing pumps, most of which require actually pushing the slide forward slightly to release pressure on the mechanism before it can be pumped. The marketers for USRAC ran with their gun’s advantage.

The Speed Pump, like its Model 70 and 94 rifles, survived another bankruptcy in 1989 when USRAC was purchased by the Belgian FN Herstal Arms Co. The 1300 enjoyed a 28-year production run, spanning more than 26 model configurations. That ended in 2006 when FN closed the New Haven plant and moved operations overseas. As part of the agreement with USRAC, FN agreed to refrain from producing it for three years, so, in 2009, FN contracted with the Istanbul Silah company of Turkey.

Although the move to Turkey seemed drastic to many loyal Winchester fans, it wasn’t actually much of a stretch in terms of actual production. Turns out, the Istanbul Silah machining firm had been making parts for FN/Winchester for some time—indeed, all but designing and assembling the 1300. Now Silah would also be assembling and shipping the completed guns as well, but at a lower price. With three years to think about it, Winchester wisely decided to improve upon the 1300 Speed Pump rather than merely bring it back.

“Silah has outstanding CNC-machining capabilities,” Hatt said. “So we were able to utilize 7075 machined aluminum that is much stronger than the alloy of the old 1300. This move allowed us to make versions of the new gun with a 3.5″ chamber, because even with the huge loading and ejection port cutouts, the receiver won’t flex like older cast-aluminum guns would. We were able to produce a stronger receiver at a lower cost.

“We kept the features that made the 1300 great—like the rotating bolt and ‘potato-peeler’ ejector—but we improved it where we saw service issues over time,” Hatt continued. “For example, the 1300 used to have a nut that held that fore-end group together, but now it’s all one solid piece. We hard-chromed the chamber and bore; we updated the styling, of course, added an excellent Inflex recoil pad and then gave it superior Invector-Plus choke tubes.

An Invector-Plus choke-tube system is included, and the back-bored barrel provides a dense, even pattern (far l.). The SXP uses a crossbolt safety that’s reversible for left-handed users (ctr.). Softening the stout recoil of the SXP is an Inflex recoil pad, a welcome feature on hard-kicking, pump-action shotguns. (r.)

“Basically, we didn’t just go buy a Turkish-made shotgun and call it our own,” Hatt said. “We re-designed it to our exact specifications and oversaw every step of its production. It’s an evolution of the 1300, but it’s a whole new gun.”

In a nod to the success of Winchester Ammunition’s iconic shotgun shells (the ammunition side of Winchester is still owned by Olin) they called it the Super X Pump, or SXP for short. SXPs began rolling off the line in 2009, where they were subsequently boxed, shipped to America and received by the importation company BACO before being sold by FN’s subsidiary, the Browning Arms Co.

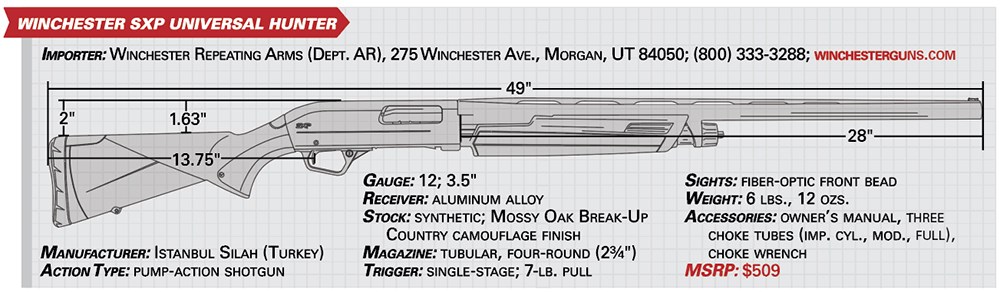

Today, the SXP endures despite a sea of competition. As of this writing, Winchester Repeating Arms offers 40 models, from specialized waterfowlers and slug specialists to trap guns and tactical variants. Many of these are offered in various barrel lengths, gauges, chamber lengths and other options. For this piece, I tested the SXP Universal Hunter in Mossy Oak’s Break-Up Country finish. The 12-ga. test unit was chambered for 3.5″ shells and had a 28″ barrel.

I found the SXP’s design to have more nuances than Hatt had time to mention. Notably, while its drop-in trigger group retains the same mechanical design as the 1300, the trigger guard and surrounding plate is made from polymer. The test gun’s trigger averaged around 7 lbs.Secondly, the back of the receiver, where it mates to the stock, is square rather than the “fishtail” shape, a legacy dating back to the Model 12. This square design allows much easier manipulation of stock fit via shims.

The SXP’s buttstock features an integrally molded sling stud, its receiver is tapped for a scope base and its barrel is back-bored. In sum, the SXP has the features of a 21st-century pump gun but still retains the classic stock dimensions and intuitive feel that made the Model 12 a favorite of wingshooters. Does its molded plastic lines look as good? To my old, subjective eyes … no.

But aesthetics aside, there’s no denying the speed of the SXP action. If the gun is fired one-handed without holding the fore-end, it will often eject the fired shell by itself. The action hastens the pumping process by giving shooters the fastest start time possible—comparable to pushing sprinters from the starting blocks exactly when the starting gun fires rather than making them anticipate it. The automatic facilitation of the pumping action also reminds shooters who may not be accustomed to pump guns to work the action when the fore-end slightly tugs on the hand. It truly is remarkable.

Control-wise, the SXP has one main feature that differentiates it from Remington’s 870 and Mossberg’s 500; its crossbolt safety is located on the leading edge of the trigger guard. Although some shooters don’t prefer it, it’s safe and functional. Current SXPs give left-handers the option of reversing it.

I liked the test gun’s gently ribbed barrel that terminates in a fiber-optic light pipe guarded by metal. While a visible front bead is overrated for most wingshooting, it’s handy for endeavors requiring rifle-type aiming, such as turkey hunting.

The “potato peeler” ejector is, in actuality, a bifurcated, thin spring clip that arches from the inside wall of the receiver outwardly toward the ejection port. This inexpensive, flexible metal part flattens out of the way when the bolt rides over it, but serves as a rebounding board that flicks the spent shell from the bolt’s extractor and out of the ejection port once the shell is pulled from the chamber and pumped rearward to clear the bolt.

Also worthy of mention is the SXP’s magazine tube, that, unlike some pump guns, is treated with a finish designed to reduce friction. This is critical for smooth and easy pumping since the fore-end, via its metal retaining collar, slides up and down this tube. After noticing the slickness of the SXP’s action, it’s puzzling why some other pump-gun makers still employ unpolished aluminum for this critical, friction-bearing component.

Also worthy of mention is the SXP’s magazine tube, that, unlike some pump guns, is treated with a finish designed to reduce friction. This is critical for smooth and easy pumping since the fore-end, via its metal retaining collar, slides up and down this tube. After noticing the slickness of the SXP’s action, it’s puzzling why some other pump-gun makers still employ unpolished aluminum for this critical, friction-bearing component.

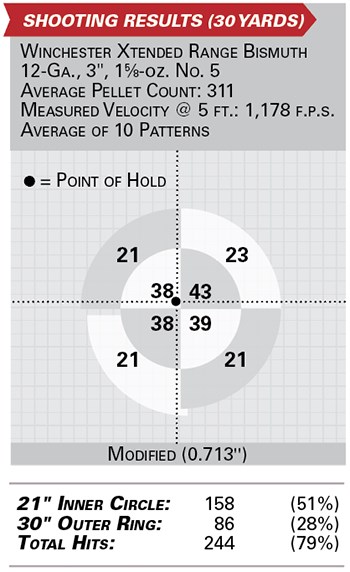

In the field, the SXP Universal Hunter came to the eye naturally just as a properly designed shotgun should. Flying targets were hit without conscious thought, indicating that the gun’s stock dimensions aligned the head down the barrel’s rib so the gun’s pattern printed where the shooter looked. Test patterns printed approximately 60 percent higher than point of aim—which is where most hunters prefer it so they can see the full bird with the bead pasted just under it while expecting the heart of the pattern to fall directly on the bird. Patterns were rich from the back-bored barrel.

While recoil from any pump shotgun isn’t mild compared to a comparable semi-automatic, the SXP’s stock is made of hard plastic with a rather pointed comb. Because of that, recoil from this fairly lightweight (6 lbs., 12 ozs.) gun cannot be described as negligible. With magnum 3″ loads, it’s stout, and with 31/2″ turkey loads, it’s up there with the hardest-kicking sporting firearms, period. I was thankful for the quality Inflex recoil pad that does what it can to spread the recoil impulse out both in terms of surface area and time, although there’s no cheating physics.

I experienced no jams with 23/4″ or 3″ shells; for a pleasant surprise, I also found that the SXP feeds Aguila’s 1¾” mini-shells without modification. Failure rate with these tiny shells was less than 20 percent, which is great for a gun not designed to run them. In sum, this is a shotgun that will run in freezing sleet when the geese fly or in fine desert sand where Rio Grande turkeys strut. I can’t think of a better, do-all shotgun for anyone, but especially a coming-of-age lad or lass who may not possess the pockets for multiple specialized guns or even one flagship semi-automatic. The fact is, in practiced hands, the SXP’s rate of fire is indistinguishable from any semi-automatic during practical hunting scenarios.

If you’re looking for a do-all, affordable and supremely reliable shotgun, do not discount Winchester’s SXP Universal Hunter. Although it may not exude the same blued-steel, made-in-New Haven nostalgia from your past, it’s actually much closer to perfection than the Model 12 ever was.

SXP Shadow Marine Defender

SXP Shadow Marine Defender

Whereas the SXP Universal Hunter is designed for use on game, an entirely different model in the SXP line is purpose-built for self-defense. Utilizing the same fast, reliable action, the Shadow Marine Defender features an easy-to-wield 18″ barrel that accepts Invector-Plus choke tubes. The barrel and magazine tube are chrome-plated for a seaworthy level of corrosion resistance. Translated, this is the gun you can stash in a closet, boat hold or truck box and worry about less than you would others—but that doesn’t mean you don’t have to clean it occasionally. The barrel comes with a pair of side-mounted Picatinny rails for easy installation of a flashlight and/or laser. It wears a fiber-optic light pipe for fast acquisition in low light, although it’s backed up by a traditional brass bead. Most notable however, is the Shadow Marine Defender’s synthetic hybrid-tactical stock that offers a great balance in terms of muzzle control, proper sight alignment and recoil mitigation, thanks to its pistol grip, interchangeable cheek pieces and Inflex recoil pad, respectively. Its two modular cheek pieces can be swapped, allowing shooters consistent and optimal head/eye alignment, even if an optic is chosen. I also like that the 7-lb., 8-oz., 38½”, five-round shotgun is available in 20 gauge as well as 12. In sum, for an all-around defensive shotgun for your home, vehicle, garage or boat, this SXP is tough to beat—and that’s even before considering its modest $519 price tag.